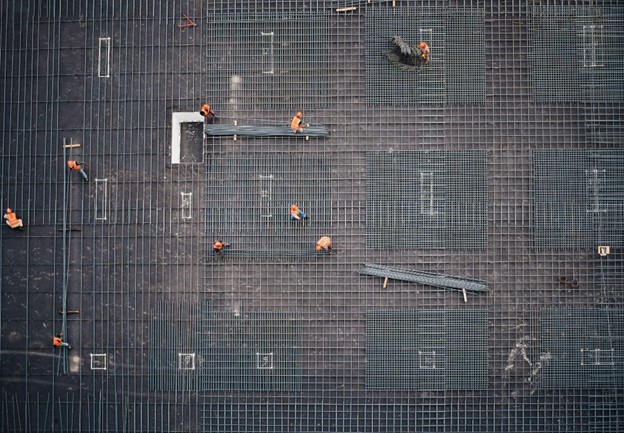

Preparation is often viewed as a key to professional success. You would do well to say that twice when talking about the industrial construction industry. In most cases, the quality of preparation will determine the quality of the project as a whole. With this in mind, keep reading for 5 points that highlight the importance of site preparation in industrial construction.

Improved Safety

Improved safety is an obvious benefit of job site preparation. Worker injury can lead to debilitating costs and legal battles that stall the entire project, so make every effort to protect workers during the site preparation phase. Some ways to accomplish this include:

- Renting a mobile storage unit to house all necessary PPE

- Applying waterproofing technology to all walkways and foundation slabs to prevent water damage

- Removing any dead timber or other debris that might present a fire hazard

- Deploying portable air scrubbers to prevent the buildup of toxic air

- Fencing the job site

At the end of the day, there is really no way to do too much to prepare the site for safety. It is worthwhile to hire a third-party consultant trained in site inspection to ensure the quality of safety measures prior to starting work.

Cost Effectiveness

Aside from the debilitating cost of a lawsuit due to safety breach, there are a number of other ways that a well-prepared site can improve cost efficiency. Some ideas include:

- Keeping all tasks and milestones on schedule, preventing blockers that lead to expensive scheduling conflicts

- Improved framework for accurate construction, eliminating costly rework scenarios

- Quick identification of all tools, machinery, and materials. Many unorganized sites often end up spending money on duplicates because they cannot find or access the originals

All in all, a small investment in site preparation will pay for itself many times over by lowering the cost of inefficiency throughout the project.

Eco-Friendliness

Energy efficient features like polyiso insulation in the walls and gravity dampers in the HVAC system are easy to identify. However, it is important to remember that these materials can’t truly help a project reach net-zero if they have to work to eliminate an energy debt created during the construction process.

Therefore, having a well-prepared job site is a great way to reduce the carbon footprint of the project as a whole. Some ways to accomplish this include:

- Carefully deploying landfill, recycling, and compost bins so that workers can mindfully dispose of waste

- Having an elite access road infrastructure. Remember that trucks hauling heavy machinery get very poor fuel economy, so every mile counts

- Providing efficient access to electricity and water so that these precious resources are not wasted

It is critical to be mindful of even the most seemingly insignificant measures, as it all adds up on industrial construction projects that take months or years to complete.

Facilitates Material Delivery

The increase in lumber, insulation, and b decking cost has made waves in the construction industry in recent years.

However, it is not just rising product prices that are influencing material costs. Other factors that are wrecking budgets include:

- Material stock outs that prevent task completion and create construction blockers

- Materials stolen from the construction site

- Materials ruined by sitting unprotected for extended periods in inclement weather

To help mitigate these concerns, many project managers are turning to a just-in-time construction model. Using this concept, materials are delivered to the construction site on an as-need basis. This greatly reduces material loss and waste.

Despite the obvious efficiency that just-in-time construction promises, communication with material vendors and delivery people has to be seamless. Too often, this is not the case. The driver parked in the middle of the road frantically trying to contact someone who knows where to take the load and piles of materials dropped off at the wrong location are all-too-common occurrences that ruin the efficiency of just-in-time construction.

Therefore, by carefully preparing the job site with the appropriate access roads and signage can greatly facilitate the material delivery process, helping optimize the just-in-time construction process.

Promotes Professional Specialization

One of the surest ways to break budgets and reduce the efficiency of a project is to have professional tradespeople doing work that is not in their area of expertise. Why have a flooring expert clearing trash from the job site? What is the benefit to having a glass handrail installation specialist going on material pickup runs?

Yet, too many unprepared sites run into these types of scenarios. They are unorganized and have to use high-value professionals to perform tasks that lower-skilled professionals could have accomplished. By focusing on job site preparation, project managers can ensure that all contractors, subcontractors, and all other workers are operating within their core competency throughout the duration of the project.

Improve the Quality of an Industrial Construction Project Through Site Preparation

The way a job site is prepared may ultimately decide the success or failure of an industrial construction project. From improved safety to better cost effectiveness, consider any of the 5 points listed above to highlight the importance of site preparation in industrial construction!